SPRINGS FABRICATION - ENGINEERED METAL PRODUCTS

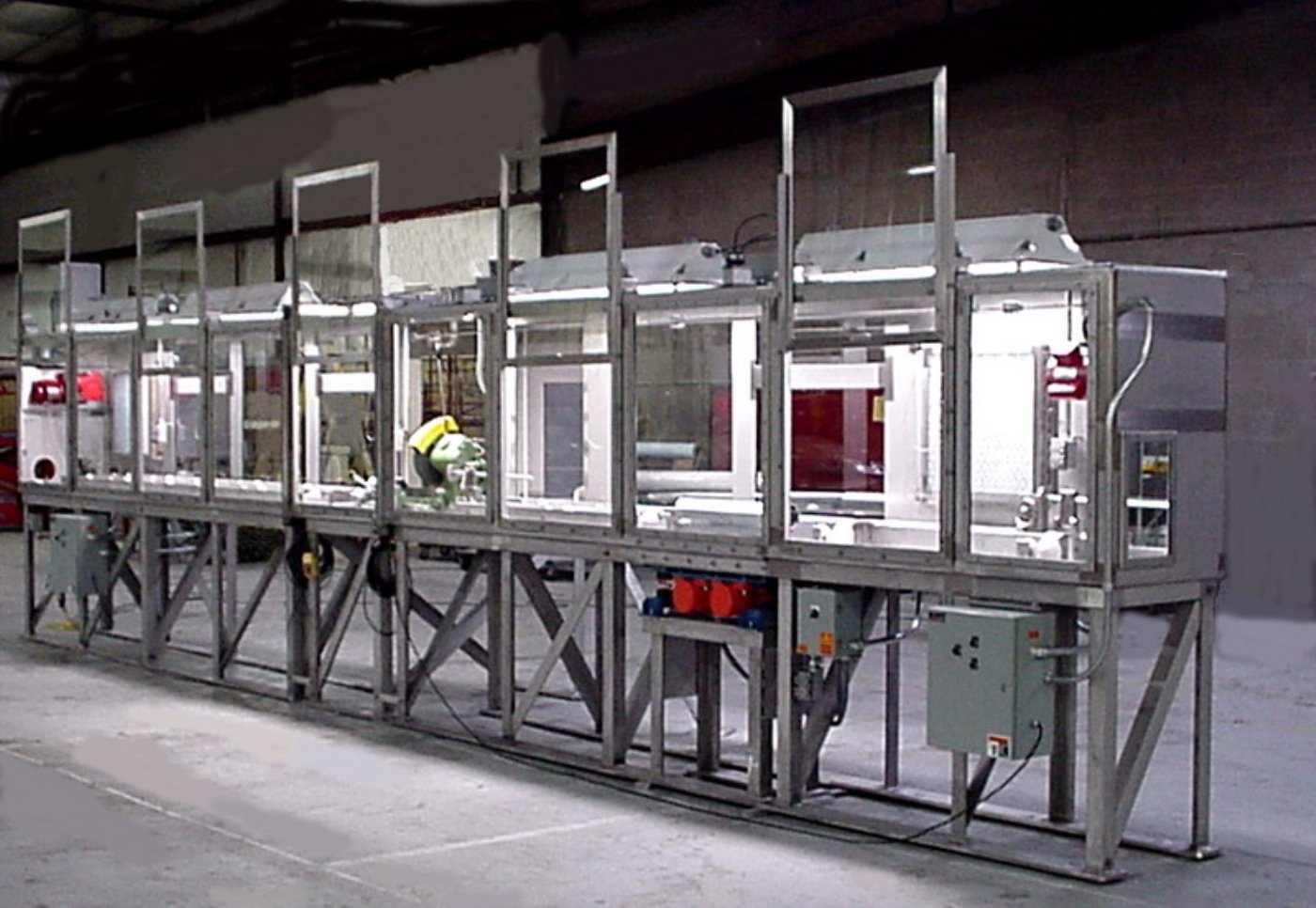

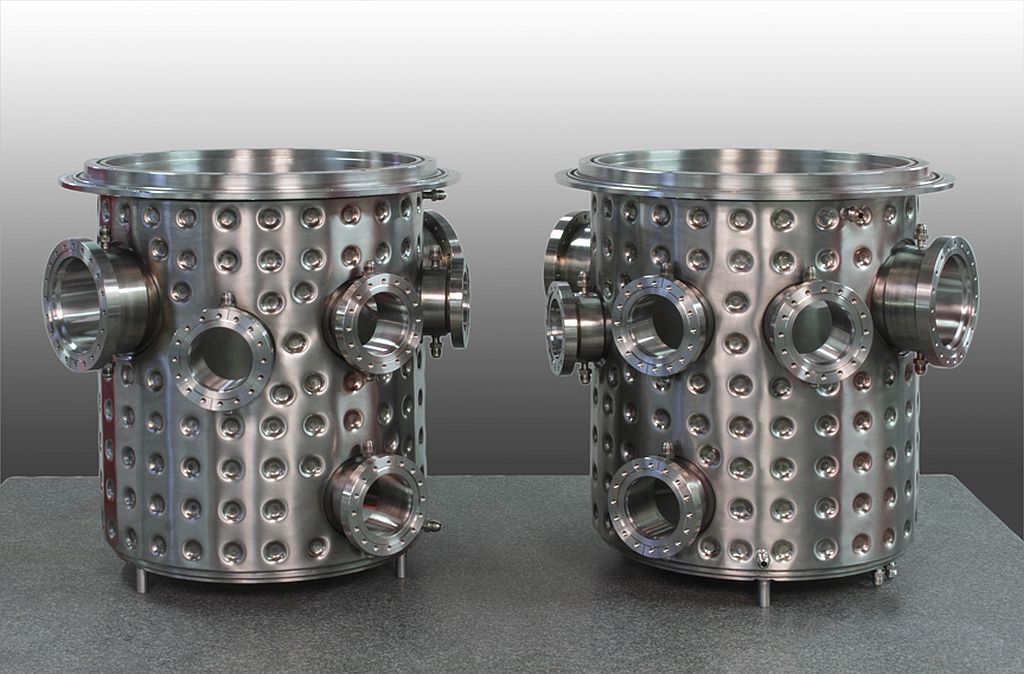

Since 1986, Springs Fabrication has been one of the top Metal Manufacturing Companies in the world; we have been serving the needs of companies nationwide with quality machining and fabrication services to deliver high-end engineered metal products in the existing and new energy, government and military, mining and remediation, and general industries. From custom designed pressure vessels to fully engineered skidded systems and an extraordinary array of industrial sized CNC machined components, Springs Fabrication is one of the nation`s premier manufacturers. Whether you require individually designed simple process parts or complex equipment and systems, your project will be handled by highly skilled, creative personnel with the goal of delivering the best in quality, service, value and delivery. We are confident that you will look at no other metal fabrication companies now that you have found us. Please request a quote today.

LATEST NEWS